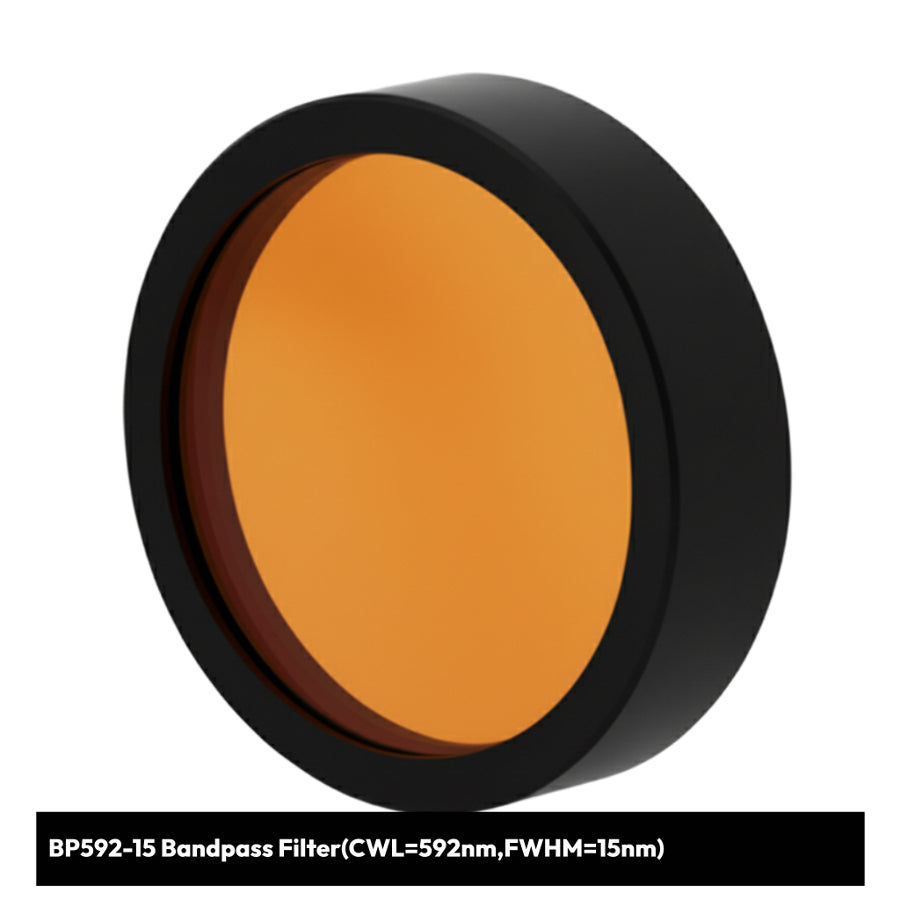

BP592-15 Bandpass Filter(CWL=592nm,FWHM=15nm)

BP592-15 Bandpass Filter(CWL=592nm,FWHM=15nm)

PN:SO3010332

Couldn't load pickup availability

Yellow-Orange Bandpass Filter for High-Precision Optical Applications

The BP592-15 is a high-performance bandpass filter engineered for demanding applications in the yellow-orange spectral region. With a center wavelength of 592nm and narrow 15nm FWHM, this filter delivers exceptional spectral selectivity and optical precision for fluorescence microscopy, sodium line filtering, and advanced analytical instrumentation.

Key Features:

- Narrow Band Precision: 592nm center wavelength with tight 15nm full width at half maximum (FWHM)

- Superior Spectral Selectivity: Narrow bandwidth for enhanced signal isolation and contrast

- High Transmission Efficiency: Optimized multi-layer coating for maximum light throughput

- Professional Construction: Durable interference coating ensures consistent long-term performance

Primary Applications:

Fluorescence Microscopy:

- Yellow fluorescent protein (YFP) imaging and analysis

- TRITC (Tetramethylrhodamine) fluorophore applications

- Rhodamine dye excitation and emission

- Multi-color fluorescence experiments

Atomic Spectroscopy:

- Sodium D-line filtering (589.0nm and 589.6nm)

- Atomic emission spectroscopy

- Flame photometry applications

- Calibration and reference standards

Industrial & Research:

- Machine vision systems requiring yellow-orange filtering

- Quality control and inspection applications

- Photometric measurements and colorimetry

- Custom optical instrument integration

Technical Specifications:

- Center Wavelength (CWL): 592nm

- Full Width Half Maximum (FWHM): 15nm

- Spectral Range: Yellow-orange visible spectrum

- High transmission in passband

- Excellent out-of-band blocking

- Narrow bandwidth for superior selectivity

Designed for professionals who require precise spectral control in the yellow-orange region, the BP592-15 provides exceptional performance for both fluorescence applications and atomic spectroscopy. Each filter undergoes comprehensive quality testing to ensure it meets the demanding specifications required for scientific research and analytical instrumentation.

Transmission & OD Data

Transmission & OD Data

The transmission curve is typical. Actual data may vary from lot to lot, you can request the raw Transmission and OD data from us.

Copy the link of the product page and send email to shop@syronoptics.com to get raw data.

Shipment & Delivery

Shipment & Delivery

For stocked products, shipment will usually be made within 5 working days after order.

For customized products, shipment will usually be made within 4-8 weeks after order.

Return & Refund

Return & Refund

Stocked Product are eligible to return within 7 days after receiving.

A flat rate of 35$ will be charged for returning.

Custom Sizing

Custom Sizing

Custom sizing is available for dimension under 60x60mm. Without mounting the thickness will generally ranging from 0.5-3mm.

For bigger size, contact shop@syronoptics.com for details.

Optical dicing refers to precision cutting processes used to segment optical materials, particularly those with specialized coatings, into smaller functional components while maintaining their structural and optical integrity. In the context of optical coating flats (flat substrates like glass, fused silica, or semiconductors coated with anti-reflective, dielectric, or other optical layers), dicing ensures these coated substrates meet exact dimensional requirements for applications in photonics, lasers, sensors, and semiconductor devices.

Methods

- Saw Dicing: Diamond-coated blades for clean cuts with minimal chipping.

- Laser Dicing: Non-contact ablation for delicate or brittle materials, reducing mechanical stress.

- Plasma Dicing: Dry etching for ultra-fine features, ideal for advanced semiconductor wafers.

Price

Dicing Service will generally cost from $50 to $125 per piece. Depending on the accuracy and size you are requesting.

Packaging

Packaging

If you need generic packaging, please leave "Generic" in the note when placing order.

In such case:

- No Branding information in Packaging Materials

- All Documentation will be generic

- We will send image of the parcel to you before fulfilling shipment

- You can use your document template for the shipment.

Feel free to contact shop@syronoptics.com for details.

Payment

Payment

Payment could be done online with Credit Card, Apple Pay, Google Pay, Wechat Pay and Alipay

For amount under $200 you can request to make payment within 7days after receiving the order.

SKU:

View full details

| Part Number | |

|---|---|

PN |

SO3010332

|

| Optical Specification | |

Center Wavelength |

592nm

|

FWHM |

15nm

|

Optical Density |

OD6@200-900nm

|

Fequently Asked Questions

What are the Thickness of the Optical Filters?

For Mounted Optics:

- 6mm (by Default)

- 3.5mm (Specified in Order Note)

For Unmounted Optics:

- 0.5mm

- 1.1mm

- 2mm

(most of the unmounted optics are having thickness of 1.1mm ~ 2mm)

What is the difference between mountings?

Unmounted:

- a bare glass optical filter

Mounted:

- Smooth Mount for protection of the optics. No thread is there on the mount.

Metric Mount:

- Start with M as prefix, usually seens as M25.5x0.5mm. Mostly used as camera filters

Imperial Mount (Usually Thorlabs):

- Start with SM as prefix, usually seen SM1, SM05 etc... Mostly used in Optical system. (You will have a SM external thread to connecting to other objects)

C-Mount:

- Very frequently used mounting. C-Mount is 1‘’-32TPI. And it is not the same thing as SM1, or M25.5x0.5mm.

Standard Mountings

Camera Mounting List

-

Our filters can be cut to match the mounting on the list. Please contact us for getting quotation.